No warehouse is complete without a fleet of forklift trucks to do the heavy lifting. But alongside the benefits they bring, there are also dangers. In fact, forklifts are the second most dangerous industrial machine in the UK after farm equipment.

It’s estimated that 100,000 forklift accidents occur per year in the UK alone. It’s a story that’s repeated across the world. In the US, it’s estimated that one in six workplace deaths involve a forklift, with 85 deaths per year relating to them. Of these accidents, it’s estimated that 70% could be prevented with standard safety measures.

Outside of collisions involving people, forklifts are often involved in accidents that cause damage to goods, resulting in higher insurance premiums, higher costs for replacements, and disruptions to operations.

Improving accident prevention

Forklift training and site safety, including clear speed signs and designated pedestrian and forklift zones, are a crucial defense against accidents and should continue to be improved and checked as the first line of protection.

No matter how good this line is, however, there are always going to be times when human error, either by a driver or pedestrian, is the cause of an issue. Camera AI solutions, such as the VIA Mobile360 Forklift Safety System, can help to further reduce accidents.

The system supports two types of AI safety features. Its front and rear cameras use AI for People Detection (PD) to spot pedestrians in the forklift’s path. If a person is detected, an alert is issued via the in-cab speaker in time for the driver to take corrective action. Given that, in the UK alone, 43% of forklift accidents between 2016 and 2019 involved pedestrian collisions, people detection AI promises to play a huge role in preventing such incidents in the future.

Boosting driver attentiveness and wellbeing

Many other incidents, involving both goods and people, are caused by driver fatigue and distracted behaviors. The VIA Mobile360 Forklift System DSS (Driver Safety System) is designed to prevent such accidents by detecting signs of tiredness and distractedness and helping the driver self-correct.

The VIA Mobile360 DSS operates through in-cabin camera that can spot when a driver is showing signs of fatigue or where they’re breaking rules, such as smoking or using a mobile phone. When it detects an issue, the DSS sounds a clear audible warning, such as “stop smoking”, to the driver to help them correct their behavior before an accident occurs or warn them that it’s time to take a break.

In all cases, the DSS is about having a digital friend that works with, not against, the drivers, to improve their safety and wellbeing, as well as enhancing general site safety. It is built to deliver only critical alerts, preventing an overload of beeping and warnings that drivers could filter out.

The American Automobile Association (AAA) recently tested similar systems in cars, looking at how effective two types of system were in mitigating common driver disengagement modes, including the driver looking down with hands off the steering wheel, and looking away with hands off the steering wheel.

The systems under test included direct monitoring systems (those that used a camera to monitor the driver) and indirect systems (those that only use steering wheel input). With its tests, the AAA found that direct systems were harder to purposefully circumvent and delivered alerts a minimum of 50 seconds sooner than indirect systems.

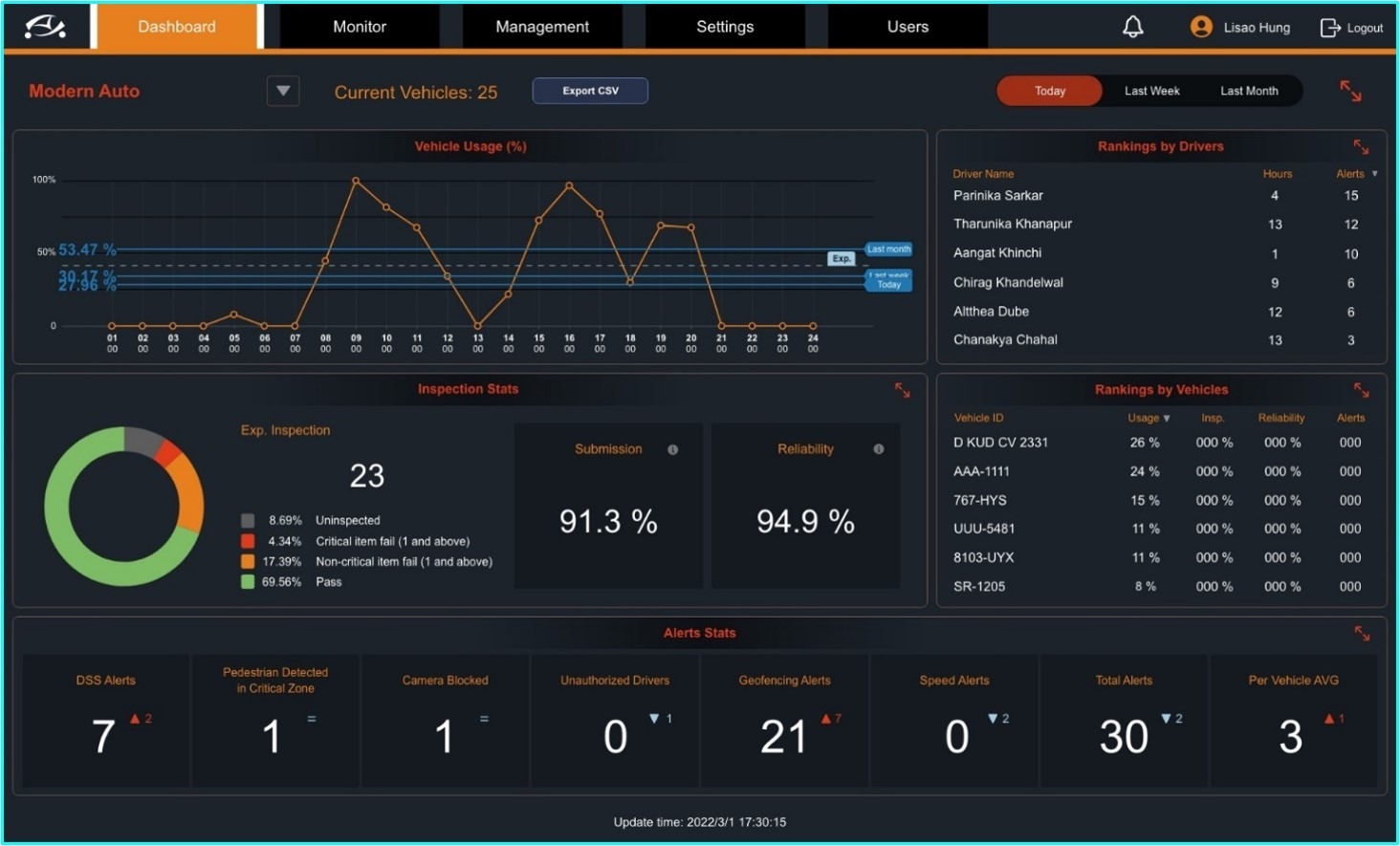

Cloud reporting and behavioral insights

Deploying a smart forklift safety system is about more than just avoiding accidents; it’s about the data it can provide and feed into a cloud reporting system. This data lets businesses track incidents, including those that were prevented from turning into an accident. It also helps managers better understand what’s really happening on the shop floor and the specific pressures drivers are facing so that they can implement changes that make a difference to safety and wellbeing.

The data collected from the DSS, for example, gives a granular insight into each driver, including how many hours they were operating and the number of alerts generated from fatigue, phone usage, or smoking. This kind of data is not available from traditional forklift safety systems, which focus on external factors.

Again, this data isn’t about spying on drivers, but creating the intelligence to make their job better. For example, if drivers have a high number of fatigue alerts on certain days, an analysis of shift patterns may highlight there’s an issue, and that work shifts need to be redrafted. The data can also help identify drivers that need additional training.

The VIA Mobile360 Forklift Safety System can be fitted to many different types of forklifts, providing key intervention at the point of danger, while intelligently delivering insight to better inform safety decisions and training. With the ability to lower costs by reducing accidents (to people and goods), as well as delivering data that helps better plan warehouse operations, smart forklift safety systems are a critical step of any business’s digital transformation journey.

Find out more about how the VIA Mobile360 Forklift Safety System DSS works, watch the video.